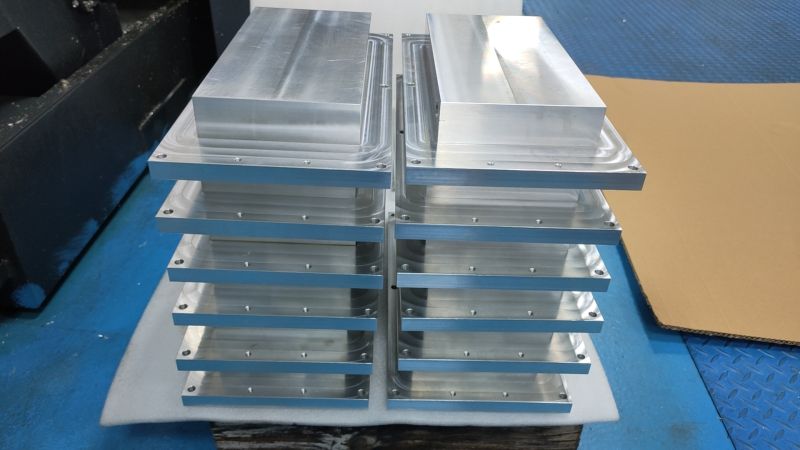

We recently made a small batch of CNC machined custom parts. In the process of batch processing, how do we ensure the accuracy of the whole batch of parts?In the mass manufacturing of CNC parts, to ensure efficiency and accuracy can start from the following aspects.

For efficiency, the first is proper programming.

The tool path is optimized during programming to reduce empty travel and unnecessary cutting actions, so that the tool can be processed in the fastest and most direct way. For example, when milling surfaces, efficient milling strategies, such as two-way milling, can reduce the tool movement time outside the processing area. The second is the choice of tools. According to the part material and machining requirements, select the appropriate tool material and tool type. For example, when processing aluminum alloy parts, the use of high-speed steel tools can improve the cutting speed, thereby improving the processing efficiency. Moreover, it is necessary to ensure the service life of the tool, replace the worn tool in time, and avoid the processing speed decrease due to tool wear. In addition, reasonable arrangement of processing procedures is also very important. Centralize the same type of processing to reduce the number of clamping times, for example, all milling operations can be performed first, and then drilling operations. At the same time, the use of automatic loading and unloading device can reduce the time of manual loading and unloading, achieve uninterrupted processing of the machine tool, and improve the overall efficiency.

In the aspect of accuracy assurance, the accuracy maintenance of machine tools is the key.

It is necessary to check and calibrate the machine tool regularly, including the positioning accuracy of coordinate axes and repeated positioning accuracy. For example, the laser interferometer is used to calibrate the axis of the machine tool to ensure the motion accuracy of the machine tool. And the stability of the clamping is also very important, choose the right fixture to ensure that the parts will not be displaced during the processing. For example, when processing shaft parts, the use of three-jaw chuck and ensure that its clamping force is appropriate can effectively prevent the parts from radial runout during rotary processing. In addition, the accuracy of the tool can not be ignored. Use high-precision tools, and ensure installation accuracy when the tool is installed, such as when installing the drill, to ensure the coaxial degree of the drill and the machine spindle. In addition, compensation during processing is also necessary. The measurement system monitors the machining size of the parts in real time, and then compensates the machining error with the compensation function of the CNC system to ensure the dimensional accuracy of the parts.

Post time: Dec-27-2024