NEW YORK, Jan. 03, 2024 (GLOBE NEWSWIRE) — The global 3D printing market is expected to grow significantly, reaching $24 billion by 2024, according to Market.us. Sales are expected to grow at a CAGR of 21.2% between 2024 and 2033. Demand for 3D printing is expected to reach $135.4 billion by 2033.

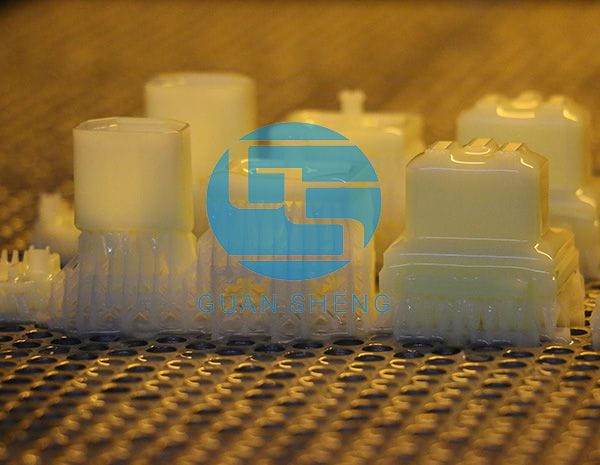

3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects by layering or adding materials, often based on digital models or designs. It is a revolutionary technology that has been widely adopted and adopted in various industries due to its unique features and benefits.

The 3D printing market refers to the global market for 3D printing technologies, materials, software and services. It covers the entire 3D printing ecosystem, including equipment manufacturers, material suppliers, software developers, service providers and end users. The constant development of 3D printing technology has expanded the scope and capabilities of this technology. Improvements in accuracy, speed, and material selection have made 3D printing easier and more versatile, allowing the production of complex geometries, custom products, and functional prototypes.

Don’t miss out on business opportunities | Get a sample page: https://market.us/report/3d-printing-market/request-sample/

(“Before you plan to invest? Review our comprehensive studies or reports by selecting a sample report. They provide an excellent opportunity to evaluate the depth and quality of our analysis before making a decision.”)

Get a deeper understanding of the market size, current market scenario, future growth opportunities, key growth drivers, latest trends and more.Full report can be purchased here.

In 2023, the hardware industry will become the dominant component of the 3D printing market, occupying a huge market share of over 67%. This can be attributed to the important role that equipment plays in the 3D printing process, including printers, scanners and other equipment required for additive manufacturing. The Hardware section examines the various technologies and machines used to create 3D objects, such as stereolithography (SLA), selective laser sintering (SLS), fused deposition modeling (FDM), and digital light processing (DLP) printers.

The high market share in the hardware segment can be attributed to the growing adoption of 3D printers across various industries for prototyping, mold processing and finished parts production. As hardware technology advances, including improvements in speed, accuracy, and material compatibility, 3D printers are becoming more efficient and reliable, fueling their widespread adoption.

In 2023, the industrial 3D printer industry will become the dominant printer type in the 3D printing market, occupying more than 75% of the market share. This can be attributed to the widespread adoption of industrial 3D printers in various industries such as aerospace, automotive, healthcare, and manufacturing. Industrial 3D printers are known for their high precision, high volumes, and ability to work with a variety of materials, including metals, plastics, and composites. These printers are mainly used for rapid prototyping, functional parts production and mold making.

The dominance of the industrial 3D printer segment can be attributed to the growing demand for advanced manufacturing technologies, demand for complex and customized parts, and the ability to achieve high-quality products at scale. The industrial 3D printer segment is expected to maintain its market leadership as industries continue to leverage the benefits of additive manufacturing for production-grade applications.

In 2023, the stereolithography industry will become the leader in the 3D printing market, occupying an important market share of more than 11%. Stereolithography is a popular 3D printing technology that uses a photopolymerization process to create solid objects from liquid resin. Stereolithography’s dominance in this field can be attributed to its ability to produce high-resolution prints with superior surface finishes, making it ideal for applications in industries such as automotive, aerospace and healthcare.

Additionally, developments in materials used in stereolithography technology have contributed to the growth of this segment, allowing the production of functional prototypes and end-use parts. The fused deposition modeling (FDM) segment has also witnessed significant growth, gaining significant market share. FDM technology involves the layer-by-layer deposition of thermoplastic materials and is popular due to its cost-effectiveness, versatility and widespread use in various industries.

Click to request a sample report and make effective decisions: https://market.us/report/3d-printing-market/request-sample/

In 2023, the prototyping industry will become a dominant force in the 3D printing market, with a huge market share of over 54%. Prototyping, an application of 3D printing, involves creating a physical model or sample that represents a product design. The dominance of the prototyping field can be attributed to its widespread use in industries such as automotive, aerospace, consumer products, and healthcare. 3D printing technology offers significant benefits to the prototyping process, allowing for faster and more cost-effective iterations compared to traditional manufacturing methods.

Additionally, the ability to create complex geometries and structures makes prototyping an indispensable tool for product development and design verification. The functional parts business also showed significant growth and captured significant market share. Functional parts refer to parts that are manufactured for an end use using 3D printing technology. The benefits of 3D printing, such as design flexibility, customization, and faster production cycles, have contributed to the widespread adoption of 3D printed functional parts across a variety of industries. In addition, the mold manufacturing industry has expanded significantly, capturing a significant market share.

In 2023, the automotive sector emerged as the market leader in vertical 3D printing, accounting for a significant market share of over 61%. The dominance in the automotive sector can be attributed to the growing adoption of 3D printing technologies in various automotive applications. 3D printing offers many benefits to the automotive industry, including rapid prototyping, custom parts manufacturing, and reduced lead times. Automakers are increasingly using 3D printing to produce functional prototypes, tooling, and even end-use parts. The technology allows them to optimize designs, reduce costs and improve overall production efficiency.

The aerospace and defense segment also witnessed significant growth and gained significant market share. The aerospace and defense industries are widely using 3D printing to produce complex components with lightweight designs, improved performance, and reduced material waste. 3D printing allows the creation of complex geometries and complex internal structures that are difficult to achieve with traditional manufacturing methods. Additionally, the healthcare segment has expanded significantly and captured significant market share.

According to materials analysis, the metal segment will become the dominant force in the 3D printing market in 2023, occupying an important market share of over 53%. The dominance of the metal segment can be attributed to the growing demand for metal 3D printing in various industries such as aerospace, automotive, healthcare and manufacturing. Metal 3D printing, also known as additive manufacturing, can produce complex metal parts with high precision and strength. The technology offers benefits such as design freedom, reduced material waste and the ability to create lightweight structures.

In particular, the automotive and aerospace industries are driving growth in the metals sector as they look to take advantage of metal 3D printing to create lightweight parts and optimize productivity. In addition, the polymers segment has shown significant growth and gained significant market share. Resin 3D printing, also known as fused deposition modeling (FDM) or stereolithography (SLA), is widely used for rapid prototyping, product development and low-volume manufacturing. The versatility, cost-effectiveness and wide range of available polymer materials have contributed to the popularity of this segment.

Plan your next best move. Purchase the data-driven analytics report: https://market.us/purchase-report/?report_id=102268.

North America will dominate the 3D printing market in 2023, accounting for more than 35%. This leadership is largely due to the region’s strong technology infrastructure, significant investments in research and development, and early adoption of advanced manufacturing technologies.

Demand for 3D printing in North America is estimated at US$6.9 billion in 2023 and is expected to grow significantly over the forecast period. The United States, in particular, has become a hotbed of innovation, with numerous startups and established companies continuing to push the boundaries of what 3D printing can do. The region’s focus on industries such as aerospace, healthcare and automotive, which actively use 3D printing technologies, has further strengthened its market position.

This report also examines the competitive landscape of the market. Some of the main players include:

The global 3D printing market will be worth US$19.8 billion in 2023 and is expected to reach approximately US$135.4 billion by 2033.

Yes, there is a huge market for 3D printing. It is widely used in a variety of industries including manufacturing, healthcare, automotive, aerospace and consumer products.

The growing use of 3D printing solutions in the manufacturing and construction sectors is expected to drive the market in the coming years.

Key players such as Stratasys Ltd, Materialize, EnvisionTec Inc, 3D Systems Inc, GE Additive, Autodesk Inc, Made In Space, Canon Inc, Voxeljet AG are the major players in the global 3D printing market.

The global semiconductor and electronics industry was valued at US$630.4 billion at the end of 2022 and is expected to grow to US$1,183.85 billion by 2032. The compound annual growth rate is expected to be 6.50% during 2022-2032.

Semiconductors are the building blocks of electronic devices. They drive advances in communications, computing, healthcare and transportation. Semiconductors have become an important part of our daily lives due to their important role in the production of electronic devices. Today, electronics and semiconductor companies have a unique opportunity to harness the power of technology to transform products, operations and business models. Manufacturers must adapt their manufacturing facilities to meet the needs of business innovation. To survive in this competitive market, flexibility and customization are key.

Market.US (powered by Prudour Pvt Ltd) specializes in in-depth market research and analysis and has a proven track record as a consulting and custom market research company and is also a highly sought after provider of syndicated market research reports. Market.US offers customization services to meet any specific or unique requirements, and reports can be customized upon request. We break boundaries and take analysis, analysis, research and perspective to new heights and broader horizons.

Post time: Apr-24-2024