In today’s fast-paced world, technology plays a vital role in various industries and one of the technologies that has revolutionized the manufacturing process is CNC machining.

The abbreviation CNC (Computer Numerical Control) is an advanced technology that uses computer software to control the movement of a machine. Although CNC machining is used in many fields, its importance in the medical industry is growing exponentially.

This article takes an in-depth look at the various uses of CNC machining technology in the medical industry, focusing on its impact on precision, customization, and patient outcomes.

CNC machining is the process of using computer-controlled machines to shape raw materials and create parts. The heart of a CNC machine is a computer control system that precisely directs the movement of tools and equipment.

Key components of CNC machines include computer control units, motors, drives and cutting tools. Through a series of programmed instructions, machines can perform complex and precise tasks with minimal human intervention.

CNC machining offers many advantages over traditional manufacturing methods. Some of the best benefits:

The medical industry has unique requirements and challenges when it comes to manufacturing devices and equipment. According to CNC experts at Artmachining, they can help the medical industry achieve better results with CNC machining processes.

Precision, accuracy and reliability are key factors in medical device manufacturing, and even the slightest mistake can have serious consequences. This is where CNC machining changes the game. This technology’s ability to achieve tight tolerances and high precision makes it invaluable for medical applications.

CNC machining makes a significant contribution to improving patient outcomes and safety. Using advanced software and the latest equipment, medical devices can be manufactured with extremely high precision, ensuring proper fit, alignment and functionality.

The reliability of CNC machining reduces the risk of errors, allowing for safer medical procedures and improved patient care.

CNC machining is widely used in all aspects of medical device manufacturing. Let’s look at some key applications. According to experts at the Chinese company cncfirst.com, most of these applications are projects commissioned by the medical industry.

Orthopedic implants such as hip and knee replacements benefit greatly from CNC machining technology.

The manufacturing process involves the use of CNC machines to shape and detail the implants to exact specifications. CNC machining allows the implants to be customized and personalized to suit the individual needs of the patient.

The technology also offers a wide choice of materials, allowing manufacturers to select materials with optimal strength, durability and biocompatibility.

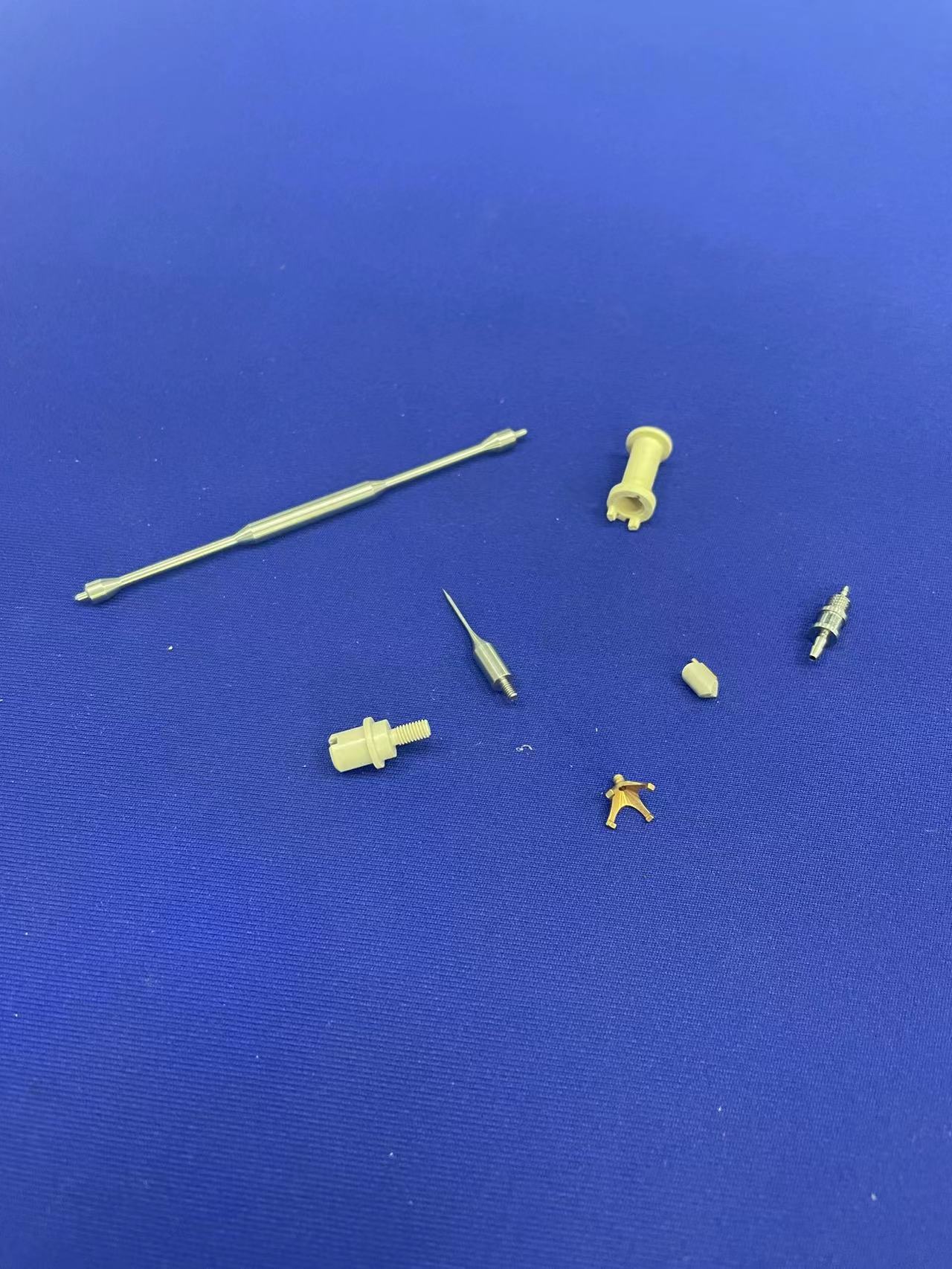

CNC machining plays a vital role in the production of high quality surgical instruments. This technology makes it possible to produce tools of complex designs and complex geometries.

These machines can precisely cut fine parts, resulting in tools with superior performance and functionality. The use of CNC machines ensures consistency in the production of surgical instruments, which is critical to maintaining their productivity and availability over the long term.

Additionally, CNC machining helps accommodate sterilization requirements so that instruments can be safely used in medical procedures.

CNC machining has revolutionized the world of prosthetics and orthotics, offering significant advantages in customization and precision. Using CNC technology, prosthetics and orthotic devices can be customized to fit a person’s unique anatomy.

CNC machines can accurately cut complex shapes and contours, producing equipment that is user-friendly, lightweight, and ergonomic. The ability to manufacture customized prosthetics and orthopedic products improves patient comfort, mobility and quality of life.

Computer numerical control machining plays a vital role in the production of critical medical device components. Components such as valves, connectors and pumps require high precision and dimensional accuracy to ensure optimal performance.

CNC machines can produce these parts with exceptional consistency, meeting the stringent requirements of the medical industry. Additionally, CNC machining facilitates rapid prototyping and iterative design improvements, allowing manufacturers to improve their products and bring them to market more efficiently.

The world of CNC machining continues to grow, with some advances targeting the medical industry. For example, significant integration of automation and robotics into CNC machining processes.

Automation can speed up production, reduce errors and increase productivity. Robotic systems can perform complex tasks with precision, further increasing the efficiency of CNC machining in medical device manufacturing.

Additionally, advances in software and simulation tools are making it easier to design and optimize medical components before manufacturing, saving time and resources.

Integrating additive manufacturing technologies such as 3D printing with CNC machining also opens up new opportunities. This combination allows you to create complex structures and combine several materials into one device. The ability to produce complex and customized medical devices using hybrid manufacturing methods offers enormous potential for the future of healthcare.

Although CNC machining brings many benefits to medical device manufacturing, there are certain challenges and considerations that must be taken into account.

A key aspect is the regulatory requirements and quality control standards governing the production of medical devices. Compliance with regulations such as the FDA’s Quality System Rules (QSR) is critical to ensuring the safety and effectiveness of medical devices.

Skilled operators and technicians are another key factor in the successful implementation of CNC machining in the medical industry. This technology requires trained technicians who can effectively program, operate and maintain CNC machines. Adequate investment in the education and training of CNC machining personnel is critical to maximizing their potential in the healthcare industry.

It is also important to recognize the limitations and limitations of CNC machining in the medical industry. Some complex medical devices or parts may require additional manufacturing processes or post-processing that cannot be achieved with CNC machining alone. Manufacturers need to evaluate the feasibility and compatibility of CNC machining for specific applications to ensure optimal results.

As CNC machining continues to dominate the medical industry, it is critical to explore the benefits of importing CNC machining services from countries like China that have expertise in this field.

China has long been considered a global manufacturing hub, offering competitive prices for CNC machining services. Lower labor and operating costs in China create cost savings for companies importing CNC machined components. In addition, the presence of a vast network of suppliers and manufacturers in China makes competition fiercer, further reducing prices without compromising quality.

China has invested heavily in technological advancement and infrastructure development, making it a leader in CNC machining. Chinese manufacturers typically have state-of-the-art CNC machines and equipment to ensure high precision, accuracy and efficiency in production. By importing CNC machining services from China, businesses can gain access to advanced technology and benefit from the expertise of experienced professionals in the field.

China has impressive manufacturing capabilities and is able to process large-scale orders efficiently and quickly. Whether it is high-volume medical equipment components or complex orthopedic implants, CNC machining services in China can meet the manufacturing needs of various medical industries. The ability to quickly scale production and meet tight deadlines is a significant advantage for healthcare businesses.

Chinese CNC machining companies understand the importance of maintaining quality control standards and regulatory compliance. Reputable manufacturers in China have established quality management systems to ensure that components produced meet the required specifications and undergo strict quality controls. By importing CNC machining services from China, businesses can rest easy knowing that they are receiving high-quality products that meet industry standards and regulations.

CNC machining services in China offer a high degree of customization and flexibility to meet customers’ specific requirements. With advanced software and skilled technical staff, Chinese manufacturers can realize complex designs, unique specifications and customized solutions. This flexibility allows the creation of customized medical components, devices and equipment to meet the specific needs of healthcare professionals and patients.

China’s comprehensive supply chain network ensures a streamlined and efficient process for imported CNC machining services. From raw material procurement to production, quality control and transportation, Chinese manufacturers have a complete supply chain management system. This ensures smooth logistics and on-time delivery of CNC machined parts, minimizing delays and disruptions in medical device production and distribution.

Chinese CNC machining companies are known for their willingness to cooperate and communicate effectively with international clients. With multilingual staff and efficient communication channels, companies importing CNC machining services from China can easily communicate their requirements, resolve problems, and maintain productive working relationships with their Chinese partners. Effective collaboration and communication are critical to the success of outsourcing CNC machining services.

CNC machining technology has changed the structure of medical equipment manufacturing and has completely changed the way medical equipment is manufactured. Its accuracy, customizability, and contribution to improving patient outcomes make it a valuable tool in the healthcare industry.

From orthopedic implants to surgical instruments, from prosthetics to critical components, CNC machining plays a vital role in improving the quality, reliability and safety of medical devices.

As technology continues to evolve and new capabilities emerge, CNC machining is poised to shape the future of healthcare. By integrating automation, robotics and additive manufacturing, this technology will further optimize processes, reduce costs and enable the creation of innovative medical solutions.

This is an exciting time for CNC machining in the medical industry, and further exploration of its potential will undoubtedly lead to significant advances that will have a positive impact on patients’ lives.

Robotics and Automation News was founded in May 2015 and is currently one of the most widely read sites in its category.

Please consider supporting us by becoming a paying subscriber, through advertising and sponsorship, purchasing products and services through our store, or a combination of all of the above.

Post time: Apr-24-2024