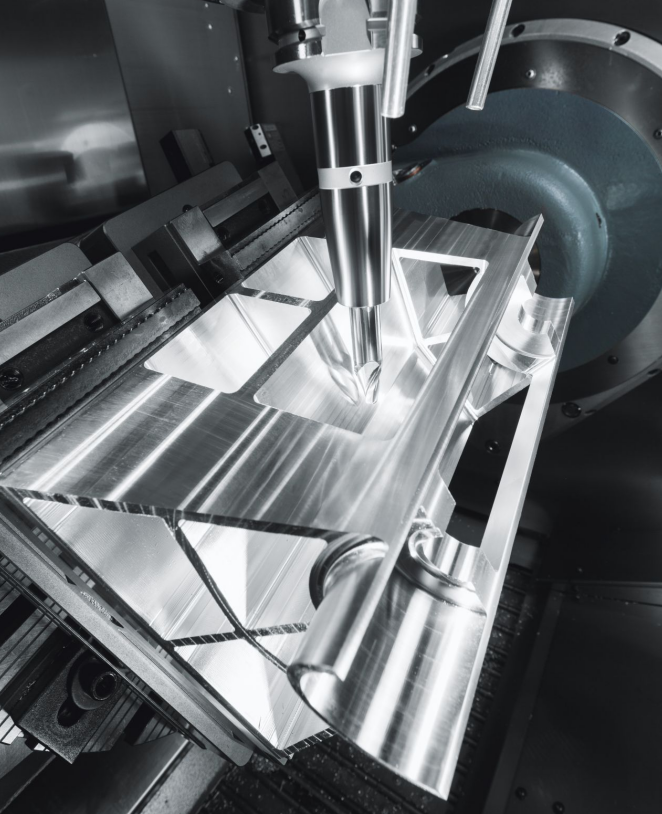

Five-axis CNC machining is a high-precision and high-efficiency machining method, which has been widely used in many fields. Compared with the traditional three-axis CNC machining, five-axis CNC machining can better control the angle and position of the tool, so as to achieve more complex machining shapes and higher machining accuracy. The applications of 5-axis CNC machining mainly include.

Aviation field: aircraft engine turbine, blade, magazine and other parts need to be five-axis CNC machining. The five-axis vertical machining centre can achieve complex surface machining of blades to ensure precision and quality, and at the same time meet the needs of the aviation field for parts with high hardness materials and high precision structure.

Aerospace field: parts such as rocket engine nozzles and satellite antennas also require 5-axis CNC machining to meet the requirements of high precision and stability.

Automotive field: the cylinder block, crankshaft and other parts of the automotive engine need five-axis CNC machining to complete, and efficiently meet the complex shape and precision requirements of automotive parts.

Mould field: injection moulds, die-casting moulds, etc. need 5-axis CNC machining to achieve the complex shape and high precision requirements, and improve the quality and service life of moulds.

Medical industry: Artificial joints, implants and other medical products with complex shapes and high precision requirements also need 5-axis CNC machining to achieve high-precision machining, improve product quality and service life, and improve the quality of life of patients.

Post time: Jul-22-2024