Aerospace Components Manufacturing

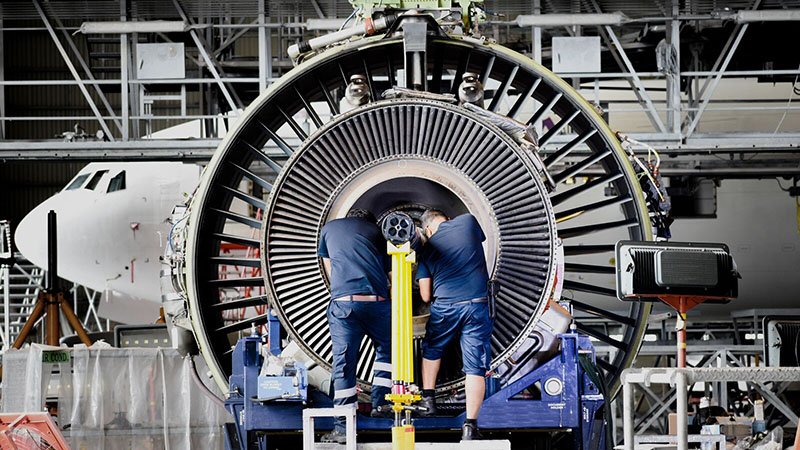

Leading manufacturers of aerospace components trust us to preserve the integrity of their designs and quite literally get their projects off of the ground on a schedule they can count on. We understand that the components we produce are on the critical path for prototype evaluation and pre-production testing for various applications in the aerospace industry, including interior aircraft components, drone components, wiring organization components, and many others.

We communicate very closely with our clients and their procurement teams throughout the production process for their design, involving an in-house subject matter expert at every stage to produce components to exact design specifications on time and budget.

Leading aerospace parts manufacturers believe that we can preserve the integrity of their designs and start their projects on schedule.

Why Choose Us

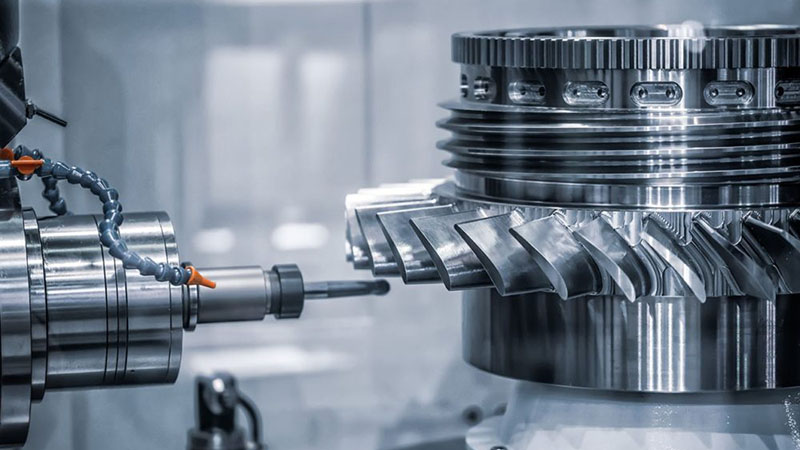

Guan Sheng specializes in reliable aerospace part prototyping and production, ranging from simple to complex projects. We combine manufacturing expertise with advanced technologies and adherence to quality requirements to bring your ideas to life. Regardless of the end use of your aircraft parts, Guan Sheng can help you reach your unique goals.

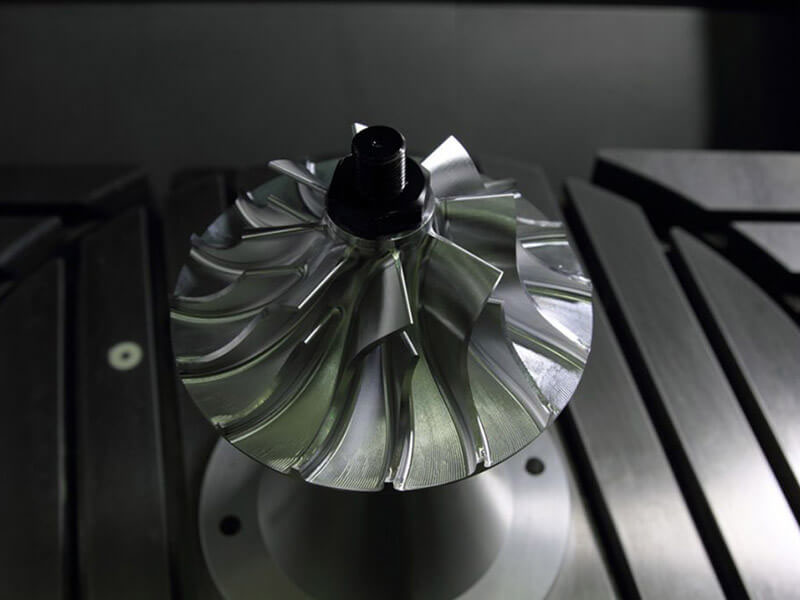

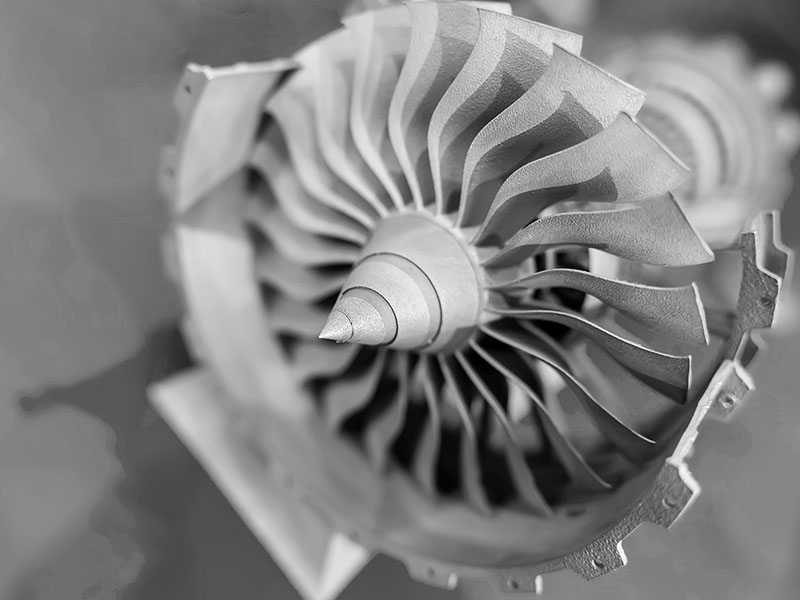

CNC Machined Aerospace Turbo Engine Prototype

Guan Sheng championed the rapid prototyping of a high-end complex aerospace engine with high tolerance requirements. Despite the strict part assembly demands and complicated turbo blade programming, Guan Sheng’s 5-axis CNC machining capabilities created a turbo engine that meets all industry demands.

Aerospace Plastic Injection Molding & Other Capabilities

To create the parts necessary for the aerospace industry, we complement our injection molding capabilities with other design technologies. Our CNC milling, cnc turning and live tool services offer precise design specs and appearance for your device in the aerospace industry. We have 10 years of service experience and have deployed all of our services, including 3D printing and urethane casting to assist in aerospace plastic injection molding as part of this evolving and progressive process. We produce highly intricate mission critical parts utilizing high temperature and high strength thermoplastic resins, including glass and carbon fiber reinforced compounds, designed to function in critical and harsh environments.

Aerospace Applications

Our manufacturing capabilities help accelerate the production of a wide range of aerospace components for unique applications. Here are some of the common aerospace applications:

● Rapid tooling, brackets, chassis, and jigs

● Heat exchangers

● Custom fixturing

● Conformal cooling channels

● Turbo pumps and manifolds

● Fit check gauges

● Fuel nozzles

● Gas and liquid flow components