About Us

Founded in 2009, Xiamen GuanSheng Precision Machinery Co., Ltd. is an experienced global manufacturer of custom rapid prototyping, tooling and OEM engineering and manufacturing based in Xiamen, China.

- 2009 Established In

- 30% Additional Markdown

- QC Team 5-person

Our manufacturing capabilities

Guan Sheng delivers high-quality precision machining with an incredible range of manufacturing capabilities. From prototyping to mass production, we help manufacture products with complex geometries and high aesthetic demands. Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

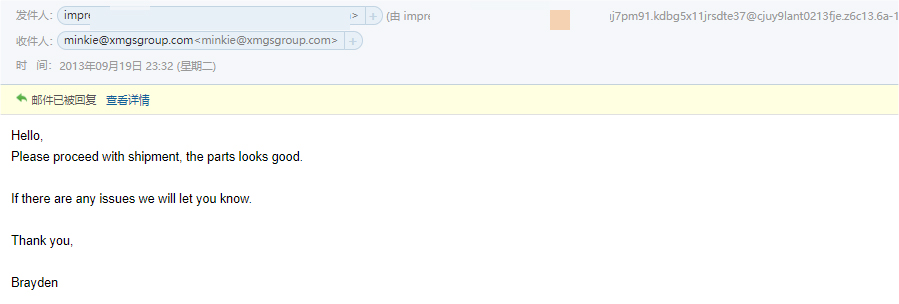

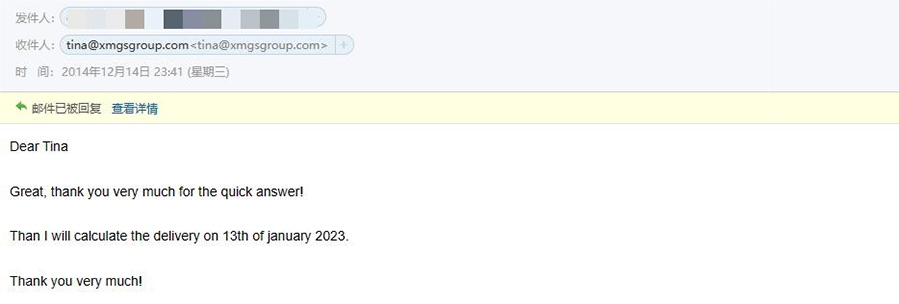

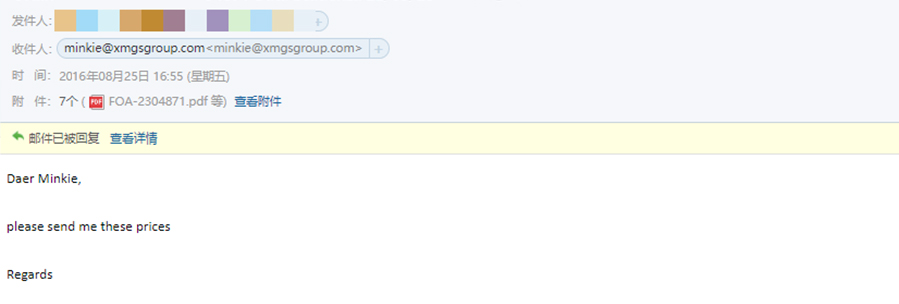

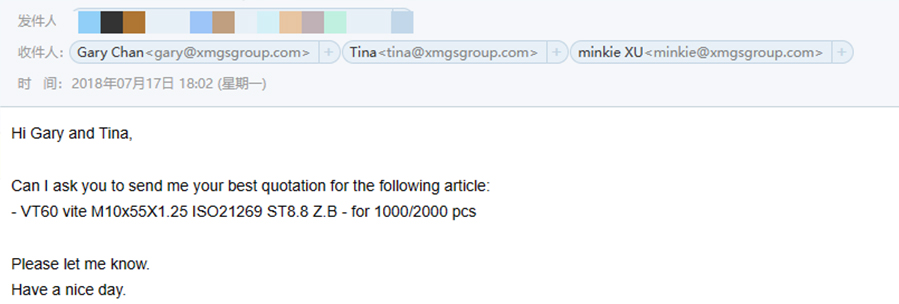

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

-

-

Our Capabilities

So far, our company has developed into a comprehensive enterprise integrating design, production, processing, sales and service.

-

Our Quality

we have a 5-person QC team to ensure that customers can receive products in good quality with using kinds of testing instruments and tools such as three-coordinate measuring instrument, two-dimensional image measuring instrument and so on.

Let's Start A New Project Today

We have a team of skilled engineers ready to support you in your product development journey from prototyping to production. When you’re ready to start your next project, simply upload your 3D CAD design files, and our engineers will get back to you with a quote as soon as possible.